CCTV News: Customs statistics show that in 2023, Jiangsu Province exported various types of ships worth 65.53 billion yuan, a year-on-year increase of 37.1%, ranking first in the country in terms of export scale.

Jiangsu: "Green Ships" Global Bestselling Shipbuilding Enterprises with Over 100 Orders in Hand

At the beginning of the 2024 New Year, Jiangsu's shipbuilding industry not only continues the prosperous momentum of 2023, but also undergoes some new changes. Before the Spring Festival, the reporter visited local shipping companies.

In a large shipbuilding enterprise in Jingjiang, Jiangsu, the production areas are bustling with activity. Staff told reporters that there are a total of 7 large ships being built at the same time in the three shipyards of the shipyard. Their self-developed new generation of low-carbon, environmentally friendly and green ships are very popular, among which the 210000 ton liquefied natural gas dual fuel bulk carrier delivered four ships in the first month of this year, breaking the record for monthly delivery of large ships.

Du Haiming from the Marketing Department of a large shipbuilding enterprise in Jingjiang, Taizhou, Jiangsu: Currently, we have 101 orders in hand with a deadweight of 13.27 million tons, including 51 liquefied natural gas dual fuel ships. The production plan for all orders has been scheduled for 2027.

The reporter learned that liquefied natural gas fuel can effectively reduce 85% of nitride emissions, 20% of carbon dioxide emissions, and 100% of sulfide and fine particle emissions compared to heavy oil fuel commonly used in large ships. It is currently the most popular green low-carbon ship type in the shipbuilding industry market.

Sun Quan from the Ship Design and Research Institute of a large shipbuilding enterprise in Jingjiang, Taizhou, Jiangsu: In 2024, the European Union will impose a carbon emission tax on the shipping industry. Our dual fuel bulk carrier can minimize the carbon emission tax for shipowners, effectively reducing operating costs throughout the entire operation cycle of the ship.

High quality development of the shipbuilding industry, full process digital construction

The shipbuilding industry has a high degree of internationalization, a long industrial chain, intensive technology, and a wide range of radiation.

In recent years, the shipbuilding industry in Jiangsu has been accelerating its intelligent transformation and digital transformation, continuously promoting high-quality development of the shipbuilding industry.

At a shipbuilding enterprise located in Chongchuan District, Nantong, Jiangsu Province, the reporter saw that it was simultaneously working intensively to build three of the world's largest container ships, two of which had already begun to take shape. The staff told reporters that thanks to the comprehensive improvement and transformation of digital and intelligent production lines by the enterprise, not only has the construction speed been improved, but also materials and costs have been saved.

Li Yong, Deputy General Manager of COSCO Chuanqi Shipbuilding Co., Ltd.: By cutting this material and then fitting other small fabrics into it, the utilization rate of the entire material is significantly increased, just like making clothes and tailoring according to specific circumstances.

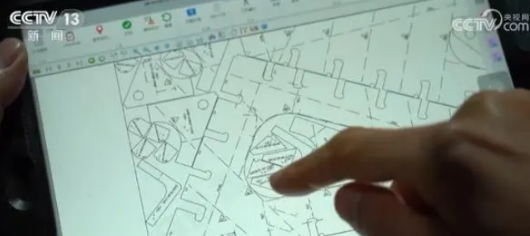

In the workshop of a company, as long as you lightly tap the screen, hundreds of computer designed component patterns will be printed on the steel plate. Then, in the next process, cutting machines and explosive welding robots can achieve precise cutting and automatic welding based on the patterns.

Reporter: Did we see this word just printed on now?

Worker from COSCO Chuanqi Shipbuilding Co., Ltd.: Yes, H182S is the name of this board. It will be installed on this fabric, and the final fabric will be assembled on this section. All of our fabrics have unique names, and we guarantee that they will not be misplaced in the subsequent process and will be matched one by one.

On the other side of the digital steel yard, thousands of different types of steel can be easily seen through an electronic display screen, and operators only need to click the computer mouse to select the materials they need. In the past, this job required a team of more than ten people to conduct manual searches.

Li Yong, Deputy General Manager of COSCO Chuanqi Shipbuilding Co., Ltd.: The operational efficiency has increased by more than 20%. Through the process of digital transformation, it has brought us great benefits in reducing costs and increasing efficiency.

Developing into a momentum to build an advanced manufacturing industry cluster for shipbuilding and marine engineering

While the shipbuilding industry is thriving, there are still many challenges to be solved in promoting the industry from "high orders" to "high value" through technological innovation.

At a shipbuilding and offshore manufacturing base in Haimen District, Nantong, Jiangsu Province, a currently largest liquefied natural gas carrier with a capacity of 180000 cubic meters in China is under construction for the first time. Previously, the construction orders for such high-tech vessels had long been monopolized by foreign companies. As a project manager, Lu Jinlong has both pride and pressure.

Lu Jinlong, LNG project manager of China Merchants Industry Haimen Base: Our wind power project and PCTC (roll on/roll off transport vessel) project have achieved a localization rate of over 90%, but our high-end projects, such as our LNG (liquefied natural gas) transport vessel, currently have a localization rate of only 47%.

The reporter saw in the workshop that the construction of ship components is being accelerated, and on the other hand, a research conference on the localization of core technologies is also being held simultaneously. Researchers from the Jiangsu Shipbuilding and Marine Engineering Equipment Technology Innovation Center have established a team to provide one-on-one on-site services for this project.

Liao Qilong, Director of Business Development Department of Jiangsu Shipbuilding and Marine Engineering Equipment Technology Innovation Center: Compared to our counterparts in Japan and South Korea, our added value and product value still differ significantly. We are searching for suitable solutions and high-end talents on a global scale, grafting technology supply and demand, settling in a group of high-tech enterprises, filling technological gaps, and helping the high-quality development of the entire shipbuilding industry chain.

Industries cluster and develop into momentum. Not only with the assistance of scientific researchers, but also recently, a large-scale shipbuilding and marine industry exhibition was held in Nantong, promoting the creation of a landmark world-class advanced manufacturing cluster for shipbuilding and marine engineering.

The image content comes from the internet. If there is any infringement, please contact us to delete it